Product

For special requirements of steel products, the final physical properties required of materials cannot be achieved through the chemical composition of the steel alone. With our innovative heat treatment and surface treatment capabilities, we are able to accord our products precisely the usage properties they need for their subsequent applications.

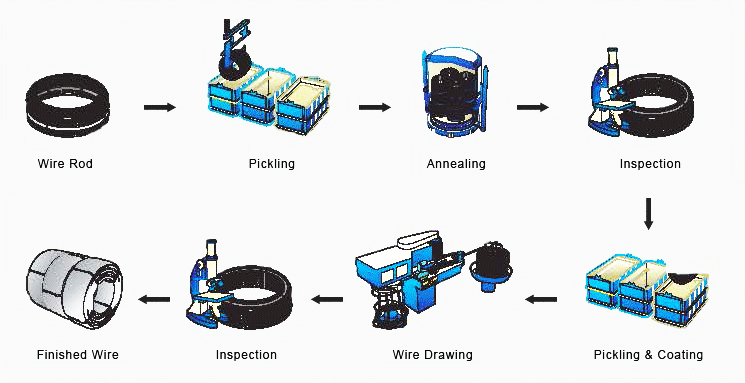

Pickling and Coating

Capacity: Automated pickling and coating line of 84000MT (185 million lbs)/ annumDuring the pickling process, several surface treatments can be executed. The line is fully equipped with cleaning, pickling and phosphating as well as lime and double lime baths. This means that a large number of surface treatments can be applied to all types of wires as untreated, annealed and drawn wire.

Annealing

Our customized bell type Hydrogen annealing furnaces assures uniformity of temperature and atmosphere to produce consistent properties that are required in CHQ wire. The spheroids are structurally consistent due to uniform temperature in the furnace, secured by high convection which is possible due to gas with good heat conductivity and high speed fans. The furnace's special AC/APEX system guarantee complete spherodization and protection against decarburization.

We have the largest annealing batch capacity with the lowest cycle times in the country. This allows us to meet urgent demands of our customers.

Wire Drawing

We have a wire drawing capacity of 60000MT (132 million lbs)/ annum ranging from sizes 1.80 - 33.0mm (0.070 - 1.299 inch)

We have provisions for eddy current testing to supply crack free material to our customers.

A new continous drawing has been recently commissioned and it’s size range 1.80mm (0.070 inch), the small sizes are available in all grades.